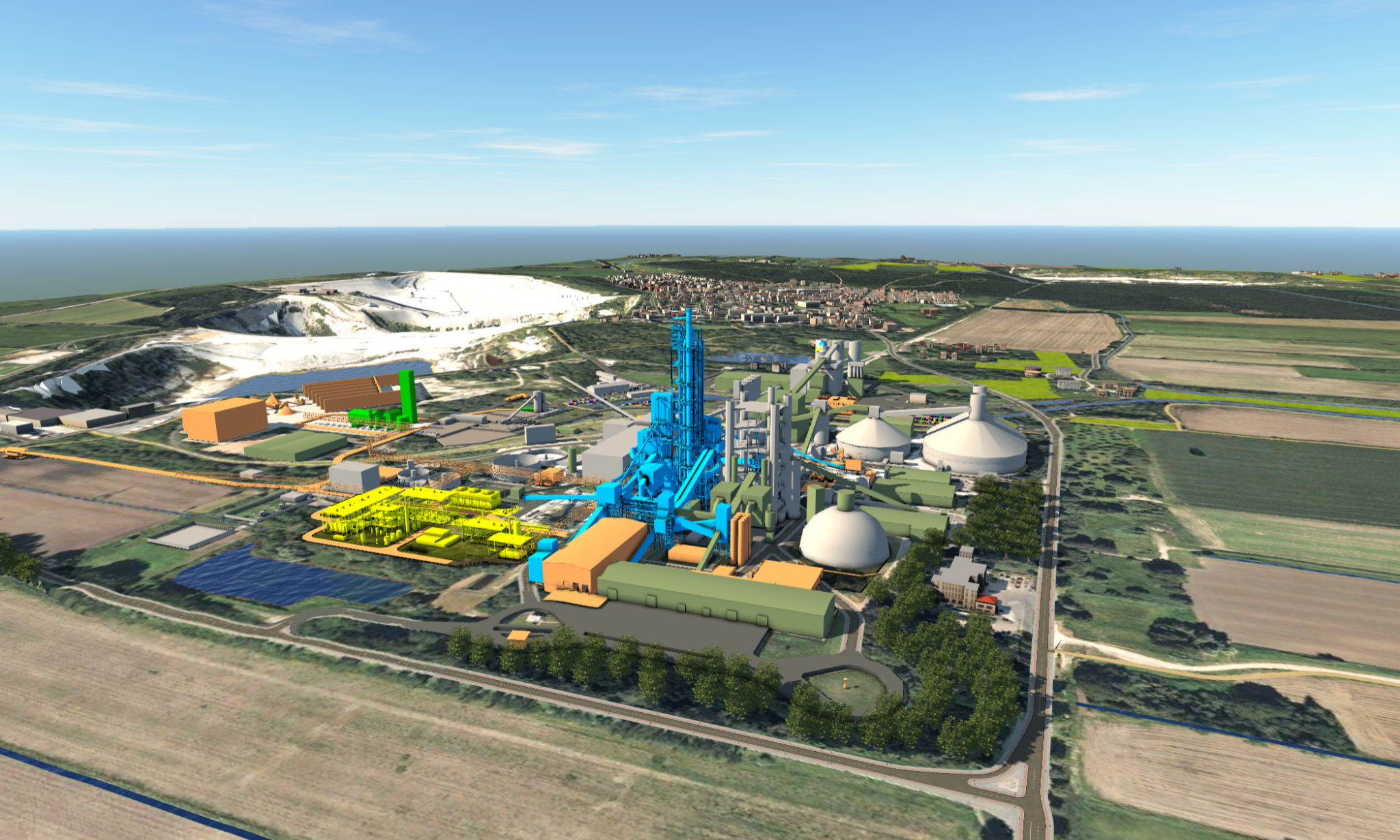

A Kiln that Changes the World

The Pioneering Initiative in Lägerdorf Drives Forward Large-Scale CO₂ Capture

Technologies for capturing CO₂ stand as a cornerstone in the global transition towards combating climate change. The aim: To capture emissions before they enter the atmosphere. Despite this crucial goal, such technologies have yet to find widespread adoption on an industrial scale. However, the pioneering project in Lägerdorf is set to bridge this gap, ushering in a new era for large industrial plants.

Holcim Germany builds a kiln in Lägerdorf that changes the world. CO₂ capture technologies play a pivotal role in this battle, involving the containment of greenhouse gas emissions to prevent their release into the atmosphere.

The significance of these CO₂ capture technologies is twofold. Firstly, transitioning entire industries to CO₂-free production – for example through renewable energy adoption – is a time-consuming process. The implementation of CO₂ capture will significantly expedite the journey towards climate-neutral economies. And time is pressing. Or rather, climate change. Secondly, relying solely on CO₂ avoidance solutions will not suffice. Certain unavoidable emissions persist, such as those from the cement industry, where a significant portion stems from inherent chemical reactions in raw materials during the production process.

How Other Industries Benefit from the Development

While CO₂ capture technology exists, its application has primarily been confined to smaller-scale projects. In Lägerdorf, where we currently emit 1.2 million tons of CO₂ annually, our aim is to eliminate these emissions in the future. As one of the country's largest CO₂ emitters, achieving this goal necessitates a significant technological leap.

Collaborating with partners such as thyssenkrupp Polysius and Linde Engineering, we are advancing CO₂ capture technology in Lägerdorf to meet the demands of large-scale industrial plants. These advancements will have ripple effects across various industries.

The introduction of the second-generation Oxyfuel process, which significantly enhances efficiency, enables the capture of nearly 100 percent of CO₂ emissions. By injecting pure oxygen into the cement kiln combustion process instead of ambient air, a CO₂-rich process gas is generated and subsequently cleaned in a Carbon Processing Unit (CPU). This ensures that CO₂ is not released into the atmosphere but is instead processed for use as a raw material.