The Resource for the Future

A New Extraction Area and Environmentally Friendly Processes Make Lägerdorf the Powerhouse of Green Cement Production

Cement production has a 160-year tradition in Lägerdorf. Short distances and a long-term supply of raw materials are essential for the climate-neutral cement plant. Holcim Germany is developing a new extraction area in the Moorwiese/Moorstücken area using environmentally friendly methods. This secures the future of the site for the next 100 years.

The heart of the cement turnaround beats on the west coast of Schleswig-Holstein. Lägerdorf is where the past, present, and future of the cement industry converge. Cement has been produced here for almost 160 years. A statue of a chalk miner in the village symbolizes this long tradition, which also forms the foundation of the community's prosperity.

Now, Holcim Germany is extending this narrative into the future, transforming Lägerdorf into the powerhouse of green cement production. By 2028, as part of the "Carbon2Business" innovation project, one of the world's first climate-neutral cement plants will be operational. This necessitates a locally secured, long-term supply of raw materials. Cement production in Lägerdorf relies solely on chalk, from which cement clinker is derived. Short distances are crucial to avoid new emissions from transportation and to ensure economically viable production.

Currently, we utilize the Heidestraße quarry in Lägerdorf for this purpose, where chalk extraction occurs through open-pit mining. However, this quarry will be depleted over the next decade. Therefore, Holcim is developing a new extraction area in the Moorwiese/Moorstücken area, ensuring raw material supply for the next 100 years – and at the same time enables environmentally friendly chalk extraction using state-of-the-art mining methods.

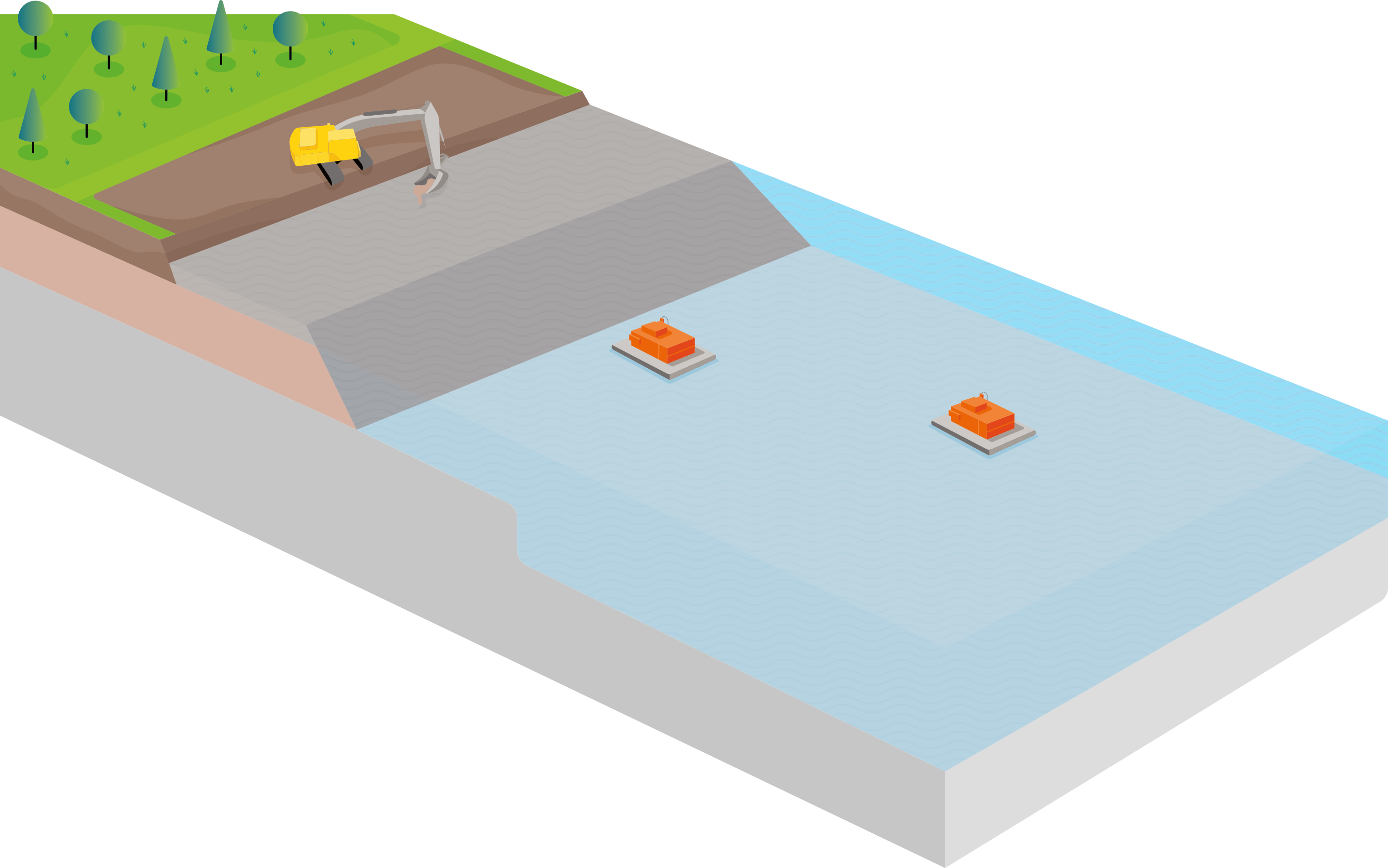

The Moorwiese/Moorstücken mining lake

The Moorwiese/Moorstücken area has been earmarked as a priority zone for near-surface raw material extraction for decades. The moors in this area were drained centuries ago. In the new extraction area, there won't be a quarry; instead, a mining lake will be created from the outset. Chalk will be dredged, slurried, and pumped ashore using floating equipment.

Underwater mining offers numerous benefits for both humans and nature. For instance, groundwater levels need not be lowered for mining, as required in open-pit mining to maintain a dry pit accessible to mining excavators. In underwater mining, the water level of the mining lake will match the groundwater level, eliminating the need for pumping pit water. Furthermore, underwater mining minimizes dust formation and absorbs noise. The previously utilized Heidestraße chalk pit will be restored, creating a protected area for flora and fauna.

- Top soil

- Sand

- Chalk